Wintone Supply Hot Sale Complete Rice Milling Plant with Competitive Price

SynopsisSupply Hot Sale Complete Rice Milling Plant with Competitive Price

Wintone Automatic Rice Milling Plant is designed and developed from superior grade raw materials in compliance with international quality standards. Meticulously tested on various quality parameters under the guidance of our experienced professionals, this plant is recognized for its reliable performance, low running cost, less maintenance, longer service life and enhanced durability.

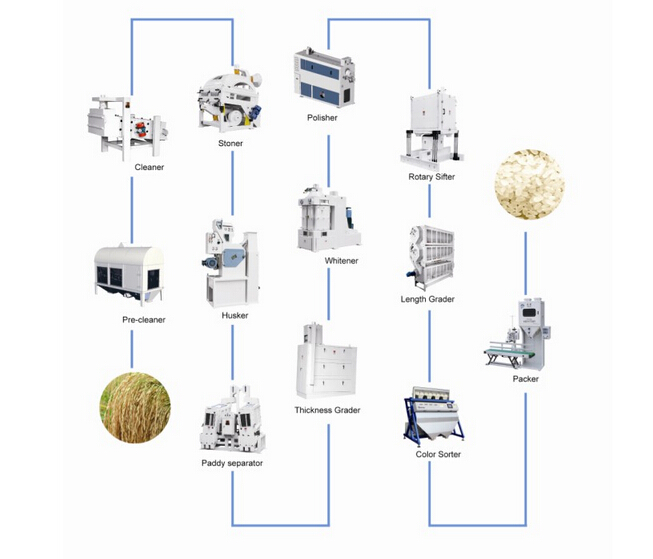

How does the automatic rice milling plant work?

Rice goes into machine via vibrating screen (removing stones) and magnet unit (removing little piece of steel), and then pass through hulling room(remove the yellow husks), winnowing room, milling room(remove the brown chaff ,and then become white rice), and blowing room in turn. The machine can complete all the processing works from cleaning grain, hulling grain to milling rice. As to husk ,chaff ,blighted grain ,as well as polished rice, they are all pushed out of machine separately. This machine is a comprehensive expression for all the good qualities of varied kinds of rice-processing machines. For instance , it is arranged with a comprehensive view of situation and is designed rationally. Its structure is compact and well organized. It is of less noise and can be easily operated and reliably regulated. Rice after processed consist of less chaff and few of them are damaged (broken). The neatness of such rice may be up to above standard. It consumes less power and is efficient in work. It is indeed a Combined Rice Milling of a new generation.

The basic rice processing processes:

|

Pre Cleaning

|

Removing all impurities and unfilled grains from raw paddy

|

|

De-stoning

|

Separating small stones from paddy

|

|

Parboiling (Optional)

|

Improving the nutritional quality and milling recovery percent during husking and polishing / whitening operation

|

|

Husking

|

Removing husk from paddy

|

|

Husk Aspiration

|

Separating the husk from brown rice/ unhusked paddy

|

|

Paddy Separation

|

Separating the unhusked paddy from brown rice

|

|

Whitening

|

Removing all or part of the bran layer and germ from brown rice

|

|

Polishing

|

Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel

|

|

Color Sorting (Optional)

|

Removing foreign materials such as colored, broken, immature and insected grains from milled rice

|

|

Length Grading

|

Separating small and large brokens from head rice

|

|

Blending

|

Mixing head rice with predetermined amount of brokens, as required by the customer

|

|

Weighing and Bagging

|

Preparing the milled rice for transport to the customer

|

If you have any questions about rice milling, please feel free to contact us. Our staffs will give you professional suggests about that.

Leave a reply